With energy grains such as wheat and barley so critical to livestock feeding systems and producers experiencing narrowing margins, such an innovation will improve returns and reduce cost of production.

AusScan Program Manager, John Spragg, said with the new NIR calibrations being commercialised, instruments could now determine the energy content of grain for particular animal types.

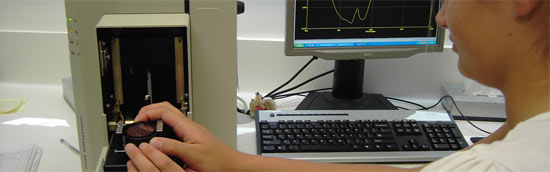

Technology commercialised as AusScan by Australia's Pork Cooperative Research Centre (CRC) is successfully using new Near Infrared Spectroscopy (NIR) tests to improve the transparency of grain quality between buyers and sellers.

“Many livestock producers and their nutritionists currently assume certain book values for the energy content of cereal grains and when these grains are added to other ingredients in a ration, the feed is often deficient or excessive in the required energy target,” he said.

Dr John Black, nutritionist and Pork CRC supported researcher with the AusScan project, said the variability of available energy of cereal grains differed in ruminants, such as cattle, goats and sheep and monogastric animals, such as pigs and poultry.

“When wheat and barley is fed to pigs and poultry, available energy can vary three megajoules per kilogram of dry matter, or 20 to 30 percent,” he said.

“However, when wheat and barley are fed to dairy and beef cattle, the energy content varies only one megajoule, or seven to eight percent.

“Quality indicators currently used by grain buyers include test weight, screenings and the degree of sprouting and the results are a very weak indication of the energy content animals ultimately derive from the grains,” Dr Black said.

Mr Spragg said the NIR technology, commercialised by the Pork CRC as AusScan, had already been adopted by grain marketers, feed mills and livestock end users.

“Also, there are now seven commercial analytical laboratories providing grain testing services using the technology.

“Likely longer term benefits will emerge when AusScan is used in grain breeding programs, providing a tool to select plant breeding lines that provide higher available energy grains,” Mr Spragg said.

Dr Brett Thomson, General Manager, Milling and Technology with AusScan licensed service provider Milne AgriGroup, said AusScan’s software allowed Milne to achieve a better assessment of the energy content of cereal grains.

“It’s traditionally quite time consuming to measure, but the AusScan software allows us to gather the information quickly and reliably.

“We can then feed it into our least-cost formulation software in a timely manner and receive the best value from our grains,” Dr Thomson said.

Mr Spragg said AusScan was now turning its attention to protein meal quality, with NIR calibrations being developed to assess the quality of canola and soybean meals.

“While we acknowledge that adopting any new grain pricing system will be challenging, the stockfeed industry is big business and optimising the energy content of feeds offers huge gains,” he said.

www.porkcrc.com.au